Silica aerogel consists primarily of silica (silicon dioxide), the same material found in quartz and sand. The aerogel structure is a gel that is subjected to a special drying process to replace the liquid component with gas, resulting in a highly porous and lightweight material. Silica aerogel is one of the least dense materials known, with density typically ranging from approximately 0.001 g/cm³ to 0.3 g/cm³. This incredibly low density is due to its highly porous structure, with up to 99% of its volume consisting of air.

Some Application Areas

- Thermal Insulation Material

- Ballistic Protection

- Ship Insulation

- Military Aircraft and Helicopters

- Military Clothing

- Electronic and Sensor Protection

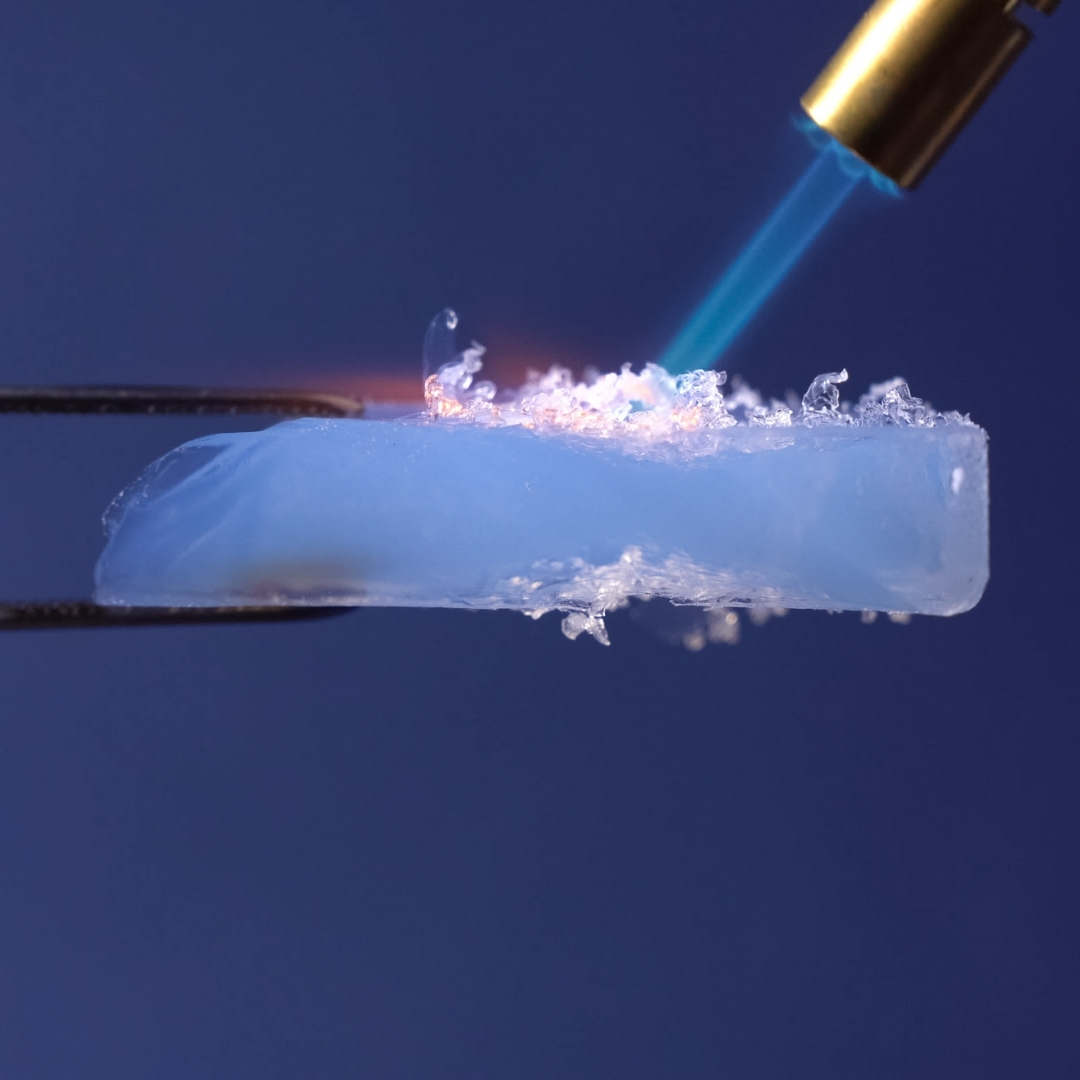

One of the most remarkable properties of silica aerogel is its outstanding thermal insulation properties. It is often referred to as the “world’s best insulator” because it effectively minimizes heat transfer. This feature makes it valuable in thermal insulation applications for spacecraft, buildings and various industrial processes. Silica airgel production involves a sol-gel process, supercritical drying, and sometimes additional modification steps to achieve specific properties. The resulting aerogel can be in various forms, including monoliths, granules, or powders.

Some potential benefits of using Silica aerogel in the defense industry include:

- Thermal Insulation: Silica aerogel has high thermal insulation properties and is resistant to high temperatures. Thanks to these features, it provides an effective solution to protect equipment exposed to high temperatures in the defense industry.

- Lightness: Silica aerogel is an extremely lightweight material, which creates no extra burden on military equipment and ensures portability.

- Impact Resistance: Silica aerogel has a durable structure and is resistant to impacts. This feature ensures the long life of the equipment used in military operations.

- Fire Resistance: Silica aerogel provides protection against fires as it is resistant to high temperatures. It increases fire safety when used in fire risk areas in the defense industry.

- Chemical Resistance: Silica aerogel has a structure that is resistant to chemicals. This feature ensures the protection of military equipment against chemical attacks.

- Signal Transmission Blocking: Silica aerogel can block the transmission of electromagnetic signals. This feature prevents military equipment from being affected by electromagnetic fields and ensures confidentiality.